LEM have announced a 2000A closed loop current transducer which uses a new approach to ripple cancellation at the fluxgate drive frequency. Reduced ripple means an increased resolution and a higher signal to noise ratio than previous generations of current transducer.

The IN2000 fluxgate type current transducer integrates a high performance DSP in the feedback loop to maximise signal processing in the digital domain. This ensures immunity to temperature effects, interference and supply voltage variation after the ADC. Offset and offset drift are also significantly improved.

Integrated DSP shapes the drive waveform

The DSP reduces fluxgate drive signal interference and ripple at a fixed frequency of 16kHz. Instead of simply switching the fluxgate voltage between positive and negative values, the drive waveform is shaped to reduce higher frequency harmonics. The remaining interference is eliminated by driving a ripple compensation coil. The DSP also includes flash memory which stores calibration parameters for individual transducers. Ripple compensation is kept constant using a local loop to keep the fluxgate drive constant. Earlier transducers allow the fluxgate excitation frequency to vary in order to keep the current amplitude constant.

High accuracy and low noise over temperature

The IN2000 delivers high accuracy and low noise over a wide temperature range. After calibration, the remaining peak-to-peak ripple is less than 50ppm (0.005%) relative to the full scale transducer output between -40 and +85 degC.

Comparison with previous generation

The graph below compares the IN2000 transducer output ripple at the fluxgate drive frequency to a previous generation transducer. Before calibration, the ripple of the compensation circuit is comparable with the spikes of the previous generation. After calibration, the ripple disappears into the noise at the output.

Shielding from interference

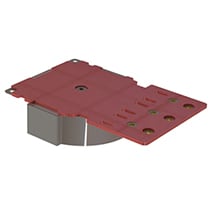

The IN2000 uses a metallic housing to shield from external sources of interference. EMC immunity is further improved by locating the fluxgate inside the primary magnetic circuit.

Overload and supply voltage fault detection

The IN2000 reacts to overload conditions and is self-protected by software that checks external and internal supply voltages. When a fault is detected, the IN2000 gives a status output on a dedicated connector pin.

Target applications

The IN2000 has a measuring range up to 3000A and is intended to deliver the high levels of performance required for increasingly demanding applications such as test equipment, medical equipment, precision motor control and metering.